Cold Shrink Cable Accessories vs. Heat Shrink Cable Accessories - Making the Right Choice

Power cable accessories are products that connect cables to power transmission and distribution lines and related power distribution devices. They generally refer to the intermediate connections and terminal connections of various cables in cable lines. Together with the cables, they form a power transmission network. Cable accessories are mainly selected based on the characteristics of the cable structure. It can not only restore the performance of the cable, but also ensure the extension of the cable length and the connection of the terminal. According to the production process, it can be divided into heat shrink type and cold shrink type. So how to choose between cold shrink cable accessories and heat shrink cable accessories? Which one is better?

Sealing

At present, there are usually two sealing methods: one is to use asphalt or epoxy resin potting method. This method is complex in process, difficult to control, and not conducive to maintenance. Another method is currently the preferred method by professional manufacturers at home and abroad - using highly elastic sealant, which has a simple process, reliable performance, and easy maintenance and installation.

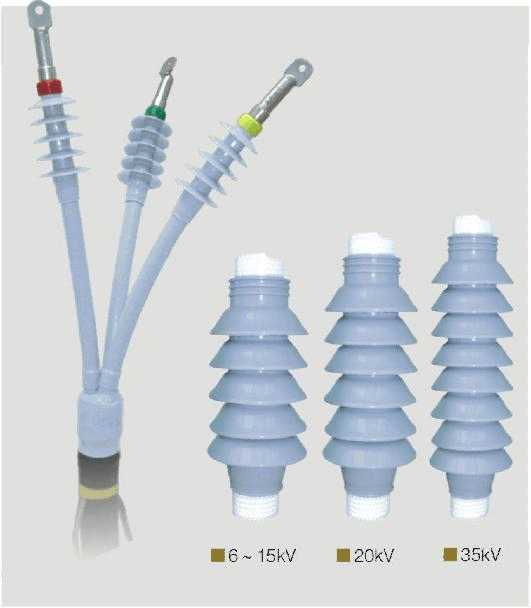

Fully cold-shrinkable power cable accessories (elastic cable accessories) use the second method, which is to use the elasticity of liquid or solid silicone rubber itself to pre-expand it at the factory, put in plastic and support strips, and set it to the designated position on site. Pull off the support strips to allow them to shrink naturally. This technology is cold shrink technology, and this accessory is a cold shrink cable accessory. This kind of cold shrinkage attachment has good "elasticity" and can avoid the thermal expansion and contraction of the cable caused by the atmospheric environment and the load level during cable operation, that is, the gap between the insulation caused by "cable breathing". The biggest disadvantage of heat-shrinkable cable accessories is that they are not elastic and cannot "breathe" with the cables.

Therefore, fully cold-shrunk cable accessories are the best choice for areas with large temperature differences and large areas affected by climate and environment.

insulation

The insulation requirements of the cable head should meet the insulation between phases and between phases and ground.

There are two types of insulation materials: silicone rubber and heat shrinkable insulation materials. When selecting, it is usually necessary to meet the insulation requirements based on the unit insulation index of the material and the thickness of the material.

Cold shrink cable accessories (silicone rubber material), the general unit insulation index is 24kV/mm, and the designed operating thickness should be 12mm thick, so that it can withstand the test of lightning impact and overvoltage.

Heat shrinkable cable accessories are made of a variety of composite materials, which are irradiated and processed to have heat shrinkability. Its unit insulation index is 1.8-2.0kV/mm, so the design thickness is 3-4mm thicker than silicone rubber material.

Relative insulation determines the safe distance that prevents charges from creeping from high potential to low potential.

Cold-shrinkable silicone rubber material has good elasticity. As long as the design is reasonable, its strong resilience will have sufficient holding power. No matter thermal expansion or cold contraction occurs in the environment, the cold shrink cable accessories are guaranteed to tightly hold the corresponding parts of the cable to prevent the inhalation of water and moisture. The safe distance from creepage can be well guaranteed. At the same time, the full cold shrink cable head Theoretically, the creepage distance is only 70mm, but for safety reasons, most designs have a running distance of 90mm.

The shrinkage temperature of the heat-shrinkable cable head is 100℃-140℃. Only the temperature during installation can meet its shrinkage conditions. When the temperature is low, because the thermal expansion coefficient of the cable is different from that of the heat shrinkable material, delamination may occur in an environment below 80°C, so cracks will appear, so that water and moisture will enter under the action of "breathing". This destroys the insulation of the cable system, which is a disadvantage of heat shrinkable materials.

The processes of cold shrink cable accessories and heat shrink cable accessories are completely different. Under normal conditions, both meet safety requirements. However, as the environment changes, cold shrink does have more advantages than heat shrink. When choosing When choosing cable accessories, comprehensive considerations must be made based on the use environment, product requirements, etc.

Related Products:Heat Shrink Cable Accessories Cold Shrink Cable Termination Accessories